Sep 2020

Three projects, three customers, three cities. Elodie, 27, is now responsible for a six-person technical platform at the Thermodyn site in Le Creusot. A rapid assumption of responsibility for this agapienne since September 2017, made possible thanks to its mobility and the skills acquired over the projects.

Industry projects

From Creusot to Ariège, via La Défense

During the past three years at agap2, I have been able to discover three customers and three different cities. The discovery of the functioning of a new company, the specifics of its products, its processes, etc. is a motivating challenge. For my first project at agap2, I first joined the Task Force set up by Areva (now Framatome), on the Le Creusot site. The Task Force was then moved to Defence. I followed suit. This allowed me to evolve within the project, going from writing technical documents to managing subcontracting and piloting projects.

At the end of this first experience at agap2, I accepted a position as Quality Business Officer at Thermodyn, again on the Le Creusot site, where I implemented actions to improve the review and acceptability of supplier quality documentation. A new project, new destination: I then spent four months at Aubert & Duval in Pamiers, in Ariège, as a pilot of a multi-trade group for the resolution of problems (Management of exemptions of parts intended for engines in aeronautics by example).

Complete Management of Supplier Quality and Technical Documentation

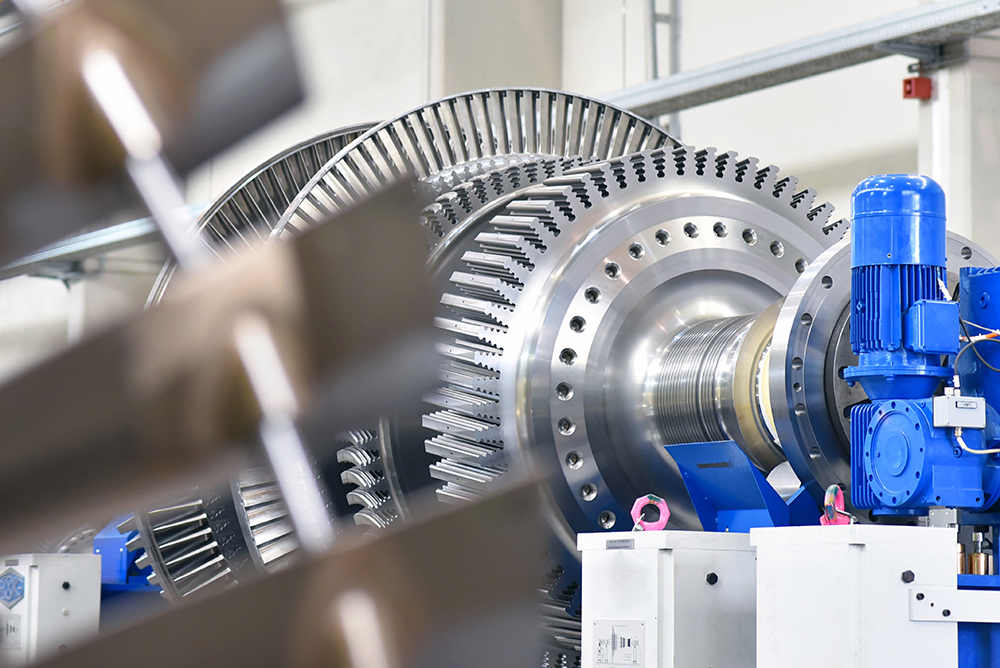

In November 2019, agap2 offered to take responsibility for the technical platform set up at Thermodyn, which designs and manufactures centrifugal compressors and gas turbines for the oil, gas and Navy markets. The technical platform made up of a team of six agapiens, receives and controls all of the supplier’s quality, and technical documentation then performs the compilation of this documentation for the issue of customer files.

The main activity consists of verifying the documentation of the components purchased from different suppliers, as they arrive and therefore, as the machine is assembled (traceability and identification of non-conformity). Part of the work is also to be done upstream in order to make suppliers aware of Thermodyn’s quality requirements.